It is a global fact that for the past few years, there has been a tremendous demand for high-quality Lifepo4 Lithium Batteries mainly attributed to the galloping rise of electric vehicles, renewable energy systems, and portable power solutions. According to a report from Grand View Research, the lithium-ion battery market will grow at a CAGR of 17.5% to register USD 129.3 billion by 2027. Such huge demands necessitate the manufacturers for a reliable and efficient product that meets the stringent quality standards. In this consideration however, companies and individuals have now increasingly been pursuing the strategies focused on top Lifepo4 Lithium Battery manufacturers to secure such sustainable energy products.

Founded in 2012, ZESE Li-ion Recycling Tech Co., Ltd. today finds its head under the new and growing changing industry landscape. From being a foundation in sales of lithium batteries, Zeseco morphed into a comprehensive enterprise that specializes in research, development, manufacturing, and sales of lithium battery energy storage power systems. The products mainly focus on things like RV lithium batteries and portable power stations. Likewise, ZESE prides itself in state-of-the-art technology and sustainable practices in meeting the world's growing energy requirements. These are some of the critical factors to consider while sourcing for high-quality Lifepo4 Lithium Battery manufacturers. It is also important to note the selection influences on the part of quality in performance and reliability during application.

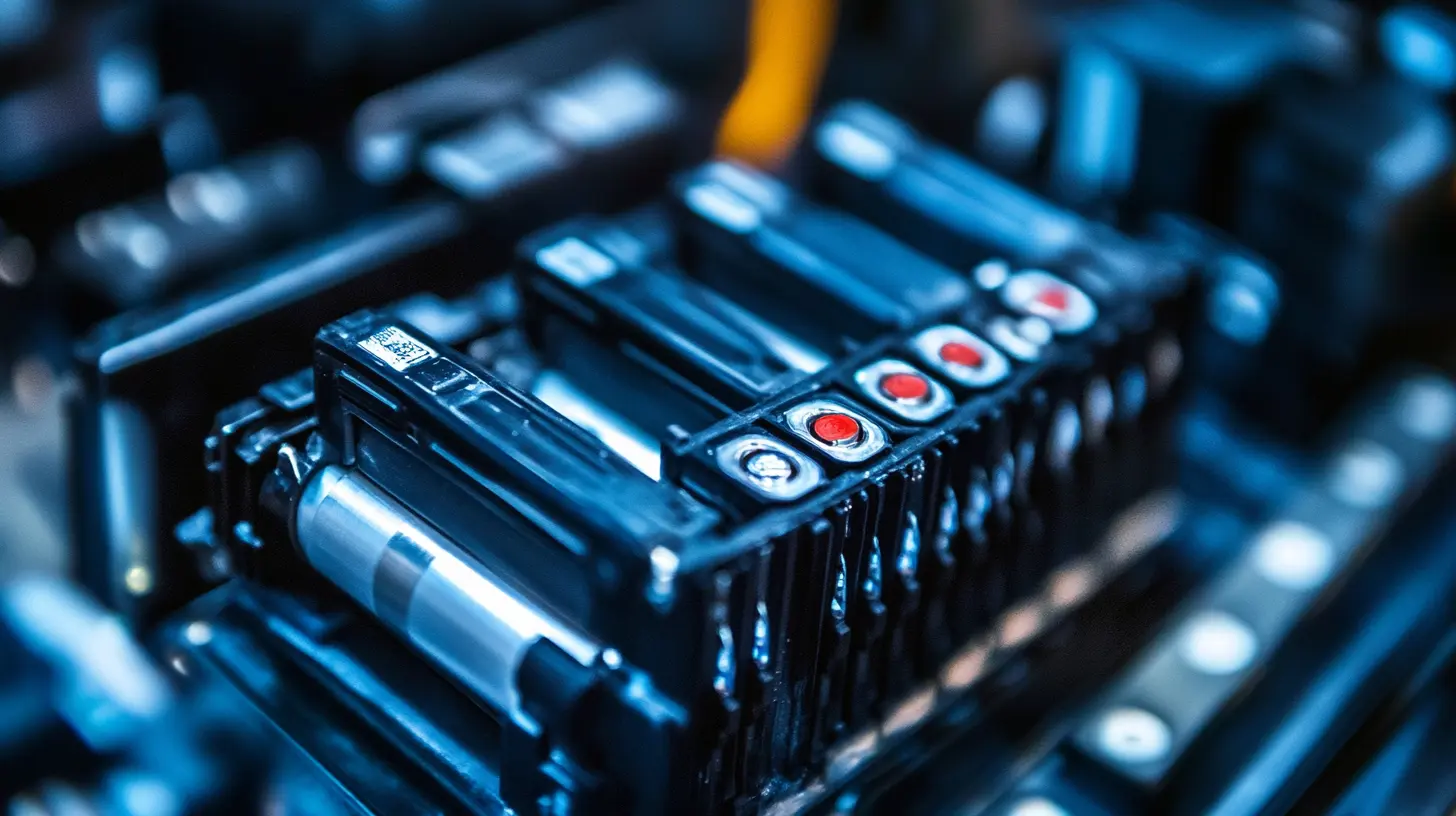

Lithium Iron Phosphate batteries have burst into the limelight for their seat-gracing of the energy storage markets and electric vehicles, with phenomenal safety, longevity, and thermal stability characteristics. A report from MarketsandMarkets posits that the world LiFePO4 battery market will increase from 2.9 billion USD in 2022 to 8.5 billion by the end of 2027, thus reporting a compound annual growth rate (CAGR) of 24.9%. This outstanding growth has been majorly driven by the burgeoning demand for renewable energy solutions and electric vehicles; if any, the application of therefore reliable and efficient technologies for batteries. One of the primary advantages of LiFePO4 technology is its stability compared to other lithium-ion chemistries. The U.S. Department of Energy highlights that LiFePO4 batteries are less prone to thermal runaway, thus being a much safer alternative for various applications. Such batteries also boast extra-long cycle life, exceeding 2000 cycles at 80% depth of discharge, thus requiring replacement less frequently and adding up to low total ownership cost. This durability is a key consideration by all manufacturers and consumers-making them very important to industries such as automotive and renewable energy, where reliability is indispensable. Furthermore, the environmental impact of LiFePO4 batteries is much lower than that of traditional lithium-ion batteries. LiFePO4 uses non-toxic materials and provides a sustainable solution that coincides with world efforts for greener technologies. According to a 2021 analysis by the International Energy Agency (IEA), utilizing LiFePO4 technology in energy storage systems could potentially emit 26% less CO2 to the atmosphere each year. This enormous reduction highlights the role of LiFePO4 batteries in achieving a more sustainable and low-carbon future while reinforcing their importance in global sourcing strategies for manufacturers concerned about sustainability.

This text discusses a variety of important parameters standing out during the international search for high-quality LiFePO4 lithium battery manufacturers, setting them quite apart from others. Ever since lithium iron phosphate (LiFePO4) technology has been gaining acceptance, the huge interest and investment in the sector have been primarily driven by good safety and cost. Recent industrial reports have shown that LiFePO4 batteries are on the comeback with much improved thermal stability and rather cheap manufacturing cost over other lithium-ion chemistries. Many manufacturers have therefore begun to focus on partnerships with knowledgeable and credible manufacturers who will deliver batteries against very rigorous performance metrics.

The strong attribute of high-quality manufacturers would be with respect to product research and development. Substance was lent to the enhanced material processes and battery design aimed at producing samples that would thrive in certain applications like electric vehicles and renewable energy storage systems. Thus, recent advances in LiFePO4 battery manufacturing techniques have begun to lead to even better cycle life and energy density, hence therefore finding its way to the applications of interest among industries that look into reliability and long-term performance. With industry reports now attesting to the ascendance of LiFePO4 in battery applications, the technology is indeed showing great promise for the local and international market.

Another parameter to consider is the manufacturer’s certification status. Obtaining products from manufacturers who have obtained certifications from accepted bodies such as UL and ISO ensures compliance with safety regulations and international standards. Besides, companies that have certified products and penetrate the international market will normally have strong supply chains and quality assurance systems. It is thus imperative to influence the manufacturers who exhibit these attributes, as they will greatly enhance the likelihood of successful sourcing maneuvers in the competitive environment of LiFePO4 battery production.

Evaluating manufacturer certifications and compliance standards is essential when sourcing high-quality LiFePO4 lithium battery manufacturers around the world. These certifications attest to the quality and safety commitment by the manufacturer and play a vital role in battery reliability and performance. Key certifications to look for include ISO 9001, which shows a manufacturer's compliance to constant quality management practices, and UL certification, which means that the products met stringent safety requirements applicable in particular markets.

Environmental compliance with standards such as RoHS and REACH is equally vital. These standards cover the manufacture of batteries that are inline with the manufacture safety interest and the other environmental interest. A manufacturer who actively meets these standards tends to display a greater sense of social responsibility and ethical practice—an important consideration for today's green market.

Furthermore, looking at the manufacturer's history regarding product recalls and compliance issues may provide insight into their reliability and accountability. A manufacturer who practices transparency should willingly share its compliance record to affirm its dedication to continual improvement in product quality and safety. By considering these certifications and compliance standards, you will further refine your selection of LiFePO4 lithium battery suppliers, ensuring a partnership with an ethical manufacturer that produces batteries that will meet global safety and performance requirements.

Another, no less important, consideration for an international supplier of high-quality LiFePO4 lithium batteries is its production capacity. Reliable energy storage solution industries require manufacturers who stand ready to fulfill demand. Assessing production capacity encompasses the facilities, technology, and workforce skills of the manufacturer-in short, a factory with newly automated equipment guarantees consistent quality and higher output, while a knowledgeable workforce quickly adapts equipment, processes, and procedures to optimize performance and troubleshoot unexpected problems.

Assessing supply chain reliability ensures continued operations. The more robust the supply chain, the more reliably it delivers production materials and lessens the risks associated with interruptions of any sort-these would include raw material suppliers, transportation logistics, and warehousing capabilities. Manufacturers are better positioned to navigate crises caused by market fluctuations or unforeseen events when they maintain these relationships with their suppliers and solid logistical infrastructure.

As a consequence, production capacity and supply chain reliability contribute heavily to the long-standing success of LiFePO4 lithium battery sourcing. Companies that prioritize these factors will be able to partner with manufacturers capable of reliably supplying these products, thereby securing their position in an ever-growing area for manufacturing.

As one captures various LiFePO4 lithium battery manufacturers of quality from the different parts of the world, customer reviews and industry reputation are big factors that substantiate all the independent decision-making. BYD made its recent decision to invest $290 million in a cathode material plant in Chile just to secure an area for reliable supply chains and reputable manufacturers of its choice. The plant will use Chile’s abundant lithium reserves, an indication that manufacturers should be investing not only in production capacity but also in maintaining a positive image and customer trust in the global market.

The International Energy Agency (IEA) states that through 2030, the lithium-ion battery industry will grow at an annual average of 23% owing to new demand in electric vehicles and energy storage solutions. Hence, consumers and businesses need to review customer feedback in evaluating manufacturers' performances and reliability. Quality, delivery timing, and after-sale service influence customer satisfaction and building future longstanding partnerships.

Also, sources like Battery University build their credibility on the opinion of the customer and thus use it to measure a manufacturer’s capability to meet stringent industry standards. Positive reviews on a network generally imply stability and skill on the part of a manufacturer, attributes that could be crucial when investing in a product as complex and costly as lithium batteries. Our stakeholders looking for insight on customer feedback and reputation can thus make their way through the complex world of battery manufacturers and secure sources for quality within their changing need.

A salient role is played by the technology development of such rapid advances in battery manufacturing to improve energy storage solutions features. Lithium iron phosphate (LiFePO4) batteries, made especially for electric vehicles, renewable energy applications, and other such, are already dominating the world market. "It is projected that the lithium battery market will grow up to $129.3 billion by the year 2027, according to Allied Market Research and which will record a compound annual growth rate (CAGR) of 18.0% from the year 2020."

It's true that new technologies can help in increasing the performance, efficiency, and sustainability of batteries as well. Innovations like that of solid-state battery and advanced manufacturing technology can really enhance energy density and safety significantly. A study conducted by the International Energy Agency (IEA) stated that only a 10% improvement in energy density would result in a 50% increase in vehicle range, a factor that is very essential for general public acceptance of electric vehicles. With such expectation from consumers as well as pressure from regulatory agencies for better products, investment in R&D becomes a necessity for long-term success.

Besides, it extends to all forms of sustainability regarding every manufacture cycle for a kind of production plant. McKinsey & Company even claims that simply adopting circular economy principles and improving production processes might save battery manufacturing carbon emissions by as much as 40%. Such evidence indicates that not only was the industry heading towards high-quality products, but towards the responsibilities of making them high-quality in doing so. Thus, manufacturers who innovate technologically will benefit in product prowess while also winning the overall esteem and sustainability of their enterprises.

While procuring top-grade LiFePO4 lithium batteries, price strategy and cost-effectiveness must probably be top on the list. The lithium battery market worldwide is anticipated to ascend to a whopping $105 billion by 2028; LiFePO4 batteries boost their usage because of their safety, longer life span, and cost efficiency. As per an analysis by MarketsandMarkets, the decreasing average rate of lithium-ion batteries has surpassed 85% from 2010, bringing enormous opportunity for the manufacturer to improve their pricing strategies,".

Using long-term partnerships with manufacturers is a major strategy to cost-effectiveness, which allows companies to negotiate for lower prices by allowing them to benefit from economies of scale. In addition to this, working with manufacturers who utilize advanced built technologies would further reduce the cost of manufacture. Research by BloombergNEF shows that about 20% of costs, translatable to lower prices to users, have been saved by manufacturers relying on automation.

Logistics and supply chain management also determine the last strategy on cost. According to a report by McKinsey, optimization in logistics can very well reduce the transportation and inventory management cost features. That of manufacturers having supply chains would boost cost efficiency and ensure their products reach consumers as scheduled. Grasp these breaths before making informed decisions on sourcing those precious LiFePO4 lithium batteries from a global market that works quite competitively.

Getting good global LiFePO4 lithium batteries means there is an aspect that tends to get overlooked- after-sales service and technical support. While selecting a manufacturer, it is imperative to check whether they have strong after-sale support so that any post-purchase issues can be addressed quickly. Good battery performance and longevity are an investment, and after-sale support can enhance both.

When scrutinizing a manufacturer, assess the dimensions of their after-sales service policies, including all warranty provisions, repair services, and provisions for accessing replacement parts. Customer-driven companies will usually dispose of returns, replacements, or repairs in a well-publicized manner. Besides, check out for manufacturers that provide full technical support, including installation, troubleshooting, and maintenance support, as this will greatly minimize downing time and improve satisfaction regarding the product.

Also, an assessment of the responsiveness of technical support during the selection process can be a good indicator of customer care. Communication flow is key; by starting a conversation with support and listening to how quickly they take to respond to your questions, you will begin to see how useful they will be once the product is in the field. If a manufacturer trains their staff to provide knowledgeable and timely help, your customers will have a more satisfying experience, which translates to a more reliable battery supply chain for you. Indeed, good after-sales support has the potential to influence significantly the performance and lifetime of LiFePO4 batteries.

Importing premium LiFePO4 lithium batteries is one of the most complex tasks globally due to interspersed challenges and regulations. Of the critical complications manufacturers face, dissimilar safety and environmental standards between countries take first place. A study by ResearchAndMarkets anticipates that the global lithium battery market is to reach $100 billion by 2027, which paints a clear picture of how important it is to abide by international and local regulations for market access.

Such regulations as the EU Battery Directive impose severe regulations related to the management and recyclability of battery life-cycles. Manufacturers should be aware of changing regulations so as not to incur vast fines against the detriment of their sustainable business. Also, they should develop synergetic relationships with suppliers that comply with these regulations; indeed, a recent McKinsey report shows that companies with a strong compliance system are 30% less likely to face a disruption of their supply chains.

Usually, global sourcing implies the immergence of tariffs and other trade policies that would often stand in the way of smooth supply chains for importers. For example, U.S. tariffs on Chinese lithium batteries would have a substantially detrimental effect on pricing and availability. Consequently, it is imperative for manufacturers to widen and diversify their sourcing policies and methods. As stated in the BNEF report, companies ought to build a mixed supply chain with local suppliers and international ones to offset risks and comply with different trade regulations. This multifaceted approach will surely go a long way in the successful navigation of the hurdles of sourcing high-quality LiFePO4 lithium batteries across the globe.

When setting up and maintaining long-term partnerships with trusted manufacturers of LiFePO4 lithium batteries, it is important that such partnerships be available to businesses as their mechanism of ensuring a steady flow supply of high-quality products. Recent industry research indicated that by 2027, the global LiFePO4 battery market is expected to reach USD 16.7 billion at a compound annual growth rate of 14.5%. Such emerging demand underlines the significance of developing strategic relationships with manufacturers that one may not only be able to do business with but also align with one's operational objectives.

Some of the factors to consider when sourcing a manufacturer include production capabilities also specified in the measures of quality control. Research in the International Journal of Energy Research shows that battery performance mostly relies on the raw materials used and the processes adopted during manufacturing. Manufacturers who put under control via quality assurance practices can reduce the possible incidences of battery faults or failures along with reliability improvement regarding the product.

Your partnership should also involve regular audits and performance assessments of suppliers towards meeting compliance with an international standard such as ISO 9001, building further on the foundations of your supply chain. The other requirement within this scope is the flexibility of the manufacturer in terms of how they communicate; best practice goes that a manufacturer should readily show one's internal operations or innovation on open lines.

Co-development opportunities could arise, and both entities can be more responsive to change in the market and technology. A report by MarketsandMarkets states that the companies which involve their suppliers in open communications tend to realize higher efficiency, i.e. percentage points of greater efficiency in operations: 22 percent in supply chains. Such opening leads to the possibility of co-development opportunities, enabling both parties to respond more competently to the market changes and technological advancements within time, hence sustainability in a partnership.

Production capacity is crucial as it determines a manufacturer’s ability to meet demand, ensuring reliable energy storage solutions for industries.

Evaluation should include the manufacturer’s facilities, technology, and workforce expertise, as these aspects influence consistent quality and output.

Supply chain reliability is vital for timely delivery of materials and mitigating risks from potential disruptions, ensuring smooth production operations.

Businesses should consider the manufacturer’s production capabilities, quality control measures, and their alignment with operational objectives to secure high-quality products.

Stringent quality assurance protocols help mitigate risks associated with battery failures and enhance the overall reliability of the products.

Integrating regular audits and performance assessments helps ensure ongoing compliance with international standards, reinforcing the supply chain's foundation.

Transparency in communication allows for better collaboration, leading to co-development opportunities and enhanced responses to market changes.

Companies that communicate openly with suppliers can experience up to 22% higher efficiency in their supply chains.

The global LiFePO4 battery market is expected to reach USD 16.7 billion by 2027, growing at a CAGR of 14.5%.

Manufacturers who are adaptable can respond effectively to market changes and innovations, enhancing the sustainability of the partnership over time.